Only the biggest and best foundries have this software Marcin Polanski, Technical Engineer (left), David Hall, Maxima Engineering Ltd (middle) and Jon Bonham, Technical Manager (right). We want our best people to work on creating a casting that delivers for you, installing the MAGMA 5 is another step to achieving this goal. It allows our highly-skilled and experienced members of staff to work with our customers to optimise the casting design which in turn will facilitate the manufacture of castings that will offer consistency order after order. The future of manufacturing has always been to improve efficiency and produce the best possible product for the customer at a cost-effective price.Īt Harrison Castings we want to embrace all that technology has to offer. This technology means we can achieve superior technical benefits to those competitors without MAGMA 5.Īutomation frees up our experienced members of staff Without having to physically build this system we can refine and perfect the casting process before we even reach the foundry. We can also virtually test how different aluminium alloys will work in each system allowing us to optimise the structure and properties of the casting.

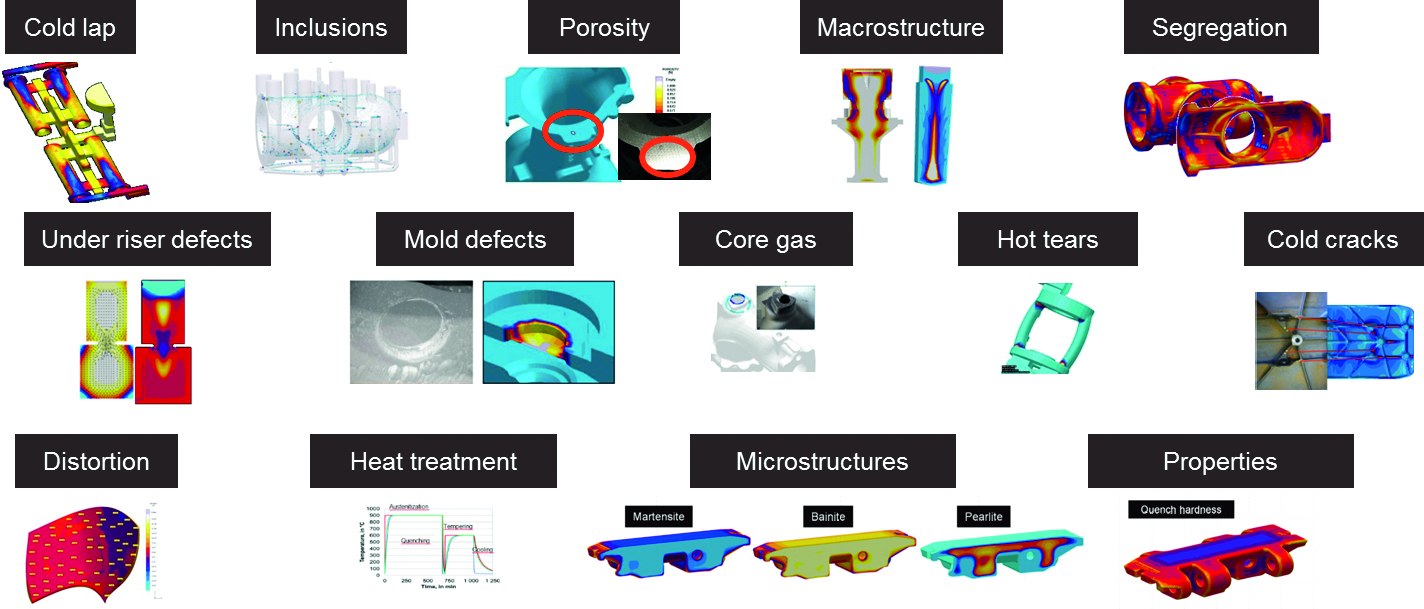

In this simulation, we can see any potential defects that we normally wouldn’t be able to see until the first casting is made. With MAGMA 5 you can simulate how this running system will look and perform. Once this system is built, we have to run our necessary tests to look for defects, performance issues and casting structure. Essentially, this is a method for pouring aluminium into one of our moulds. For a start, with a traditional CAD model we have to develop a running system. The benefits of creating a simulation to improve casting development are numerous. What are the benefits?Īdding simulations dramatically improves the production process

This data is then used to create a virtual casting design that gives us a huge amount of data to work with at our foundry. We can input quantitative objectives and our critical production variables into the software. Here’s the clever bit, MAGMA 5 works by creating a simulation of the casting. Ultimately, this technology will help us produce the highest-quality product for you whilst saving everyone involved time and money. MAGMA is the leading supplier globally of software for casting excellence and we are proud to install MAGMA 5 in our aluminium foundry. MAGMA 5 is the latest software available from MAGMA that optimises the casting process, improves production methods and helps Harrison Castings’ quest to produce defect-free castings.

0 kommentar(er)

0 kommentar(er)